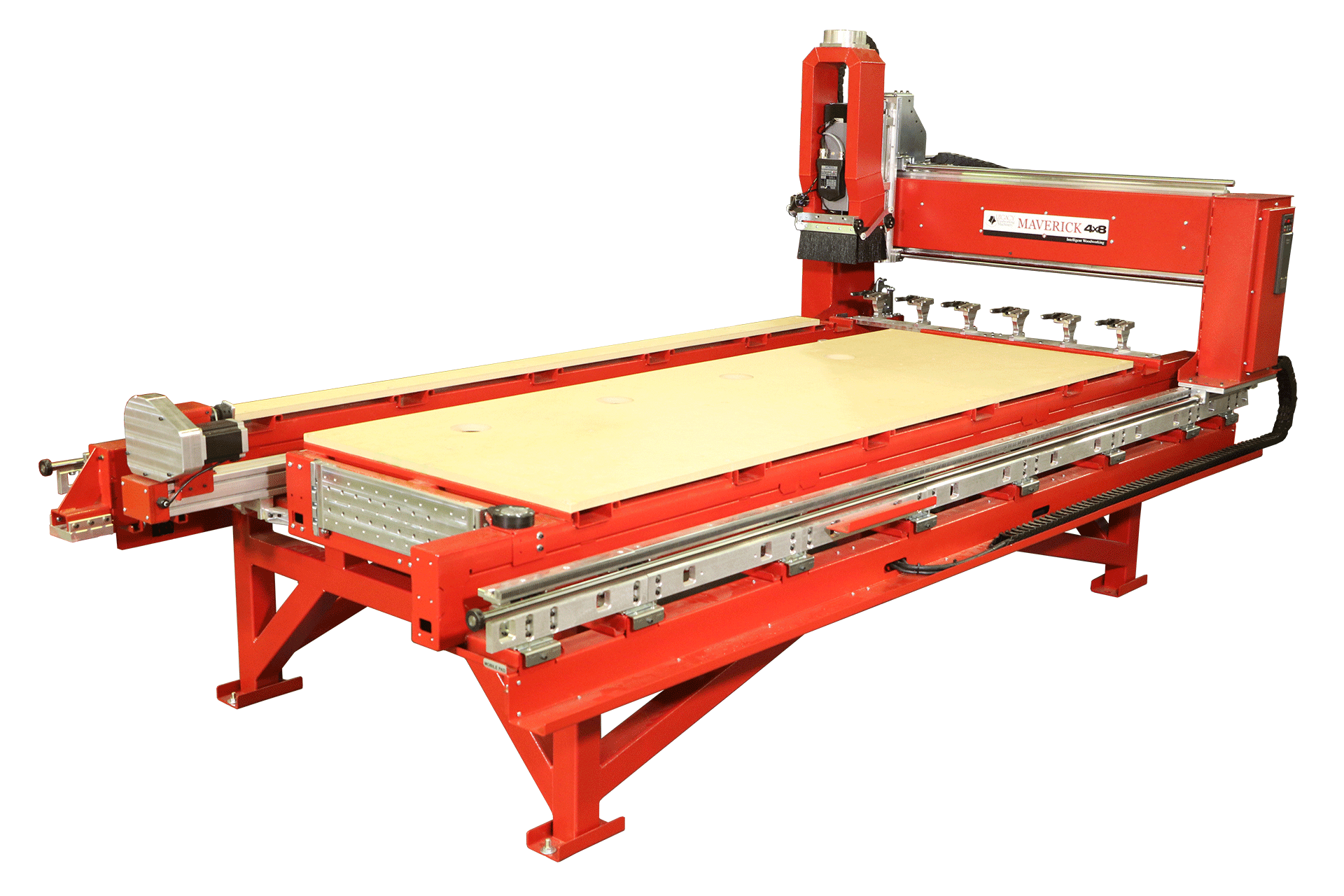

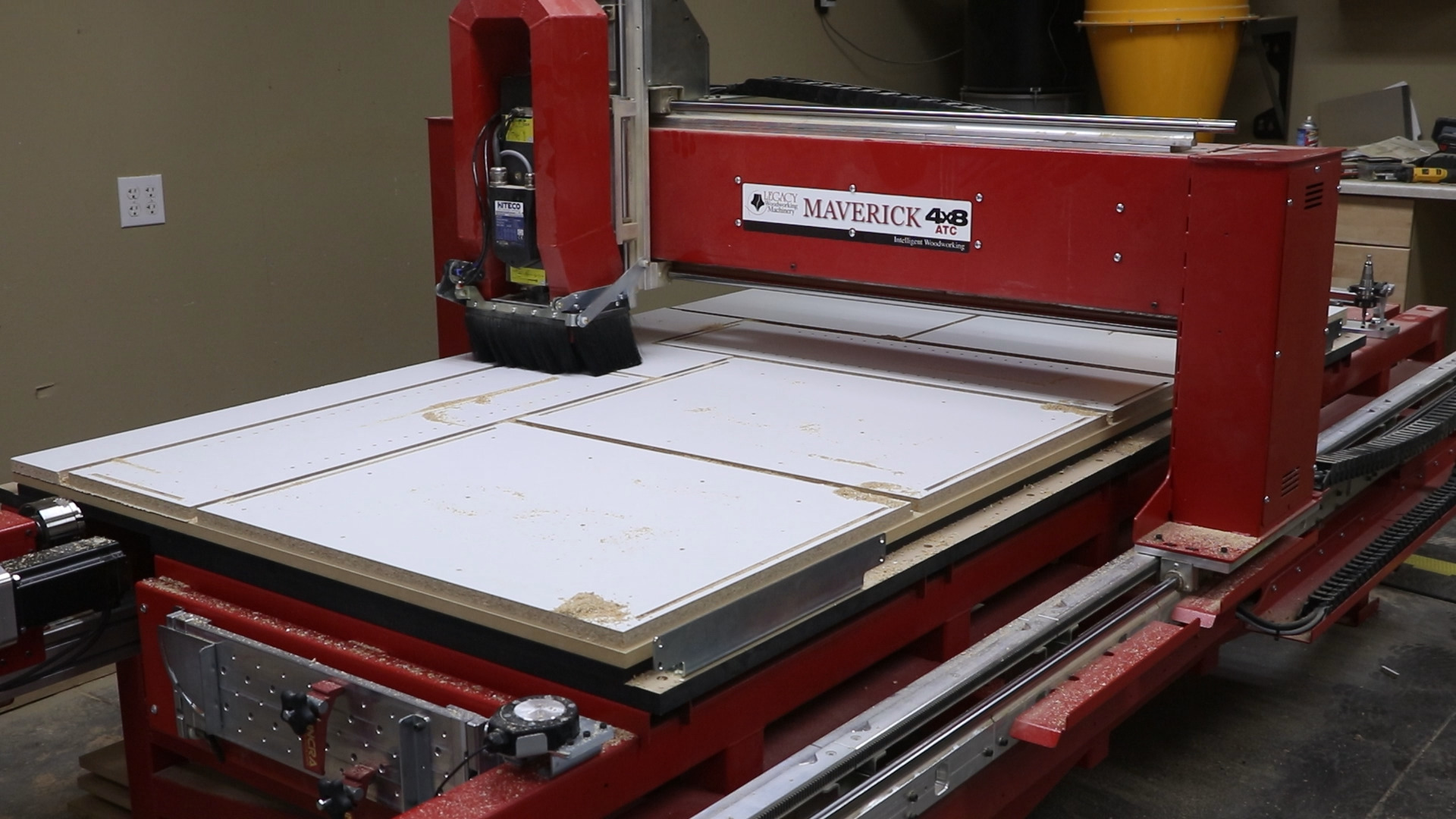

The Best CNC For Automating All Woodworking Disciples

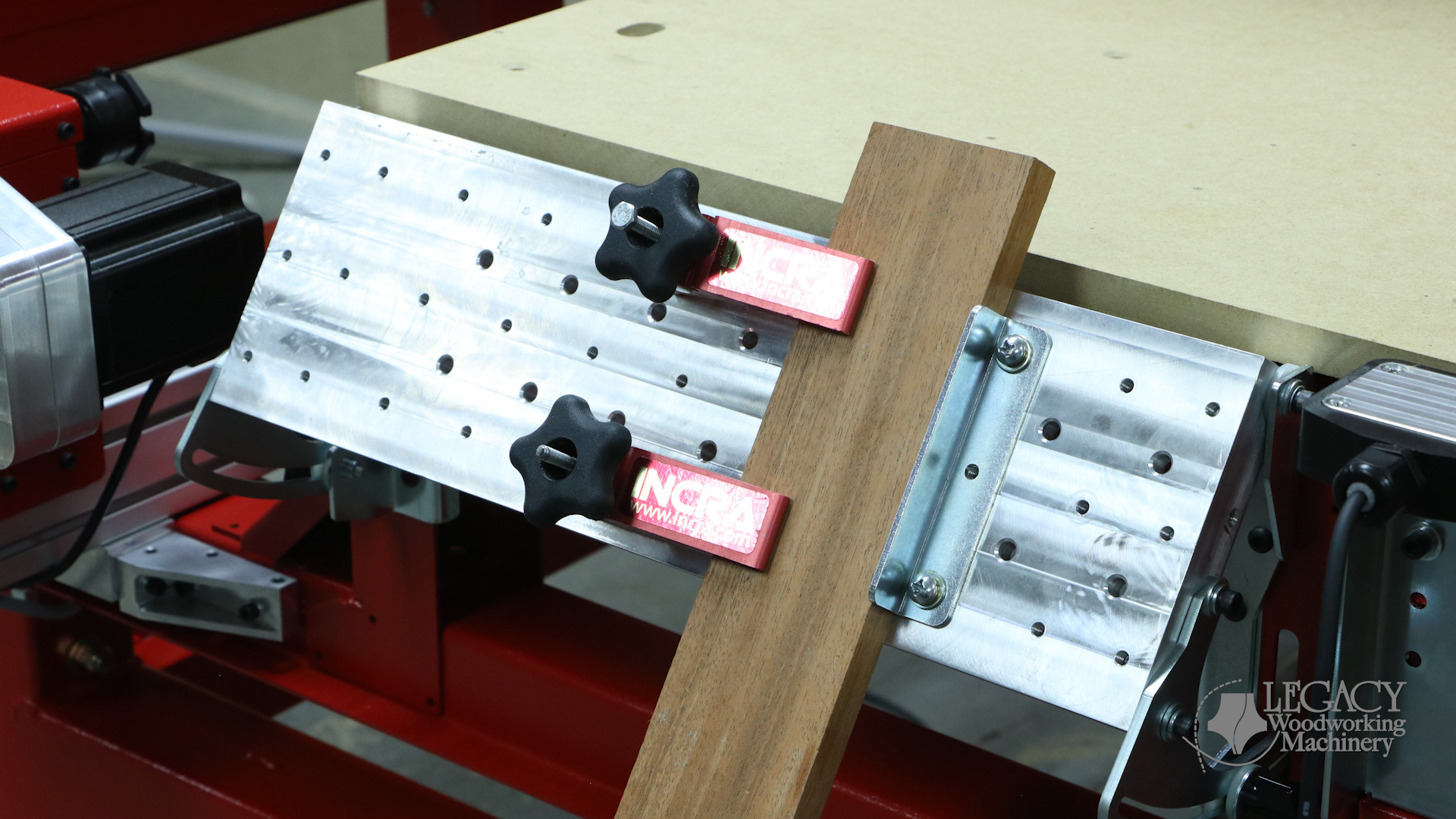

Legacy’s CNC systems feature up to three workstations which will allow you to automate most of your woodworking task. No other CNC manufacturer offers you as many CNC capabilities.

3 CNC MODELS IN 6 SIZES